Precise Load Measurement in Washing Machines: Enhancing Efficiency with Advanced Sensors

Washing machines have evolved significantly, becoming sophisticated appliances that prioritize not only cleanliness but also resource efficiency. Central to this evolution is the integration of precision sensors, particularly load cells, to accurately measure the weight of the laundry. In this detailed exploration, we will delve into the significance of these sensors, their working mechanisms, and the impact they have on the overall performance of washing machines.

Introduction

Washing machines, a staple in modern households, have undergone a transformative journey from rudimentary designs to advanced appliances incorporating cutting-edge technologies. Among these innovations, the inclusion of precision sensors stands out as a key contributor to improved performance and efficiency. This section will delve into the evolution of washing machines and the imperative for incorporating precise load measurement technologies.

A. Evolution of Washing Machines

The historical progression of washing machines traces back to simple hand-cranked devices, gradually transitioning to electrically powered agitators and ultimately to the sophisticated automatic machines we use today. This evolution, driven by a pursuit of convenience and efficiency, laid the groundwork for the integration of advanced sensor technologies.

B. Imperative for Precision in Washing Machines

The need for precision in washing machines arises from a dual perspective of efficiency and resource conservation. Traditional machines often relied on estimation methods for load sizes, leading to inefficiencies in water and detergent usage. Precision sensors, particularly load cells, address this issue by providing accurate measurements, allowing for a more judicious approach to the washing process.

Also Read: Best Washing Machine in India

Types of Sensors Used in Washing Machines

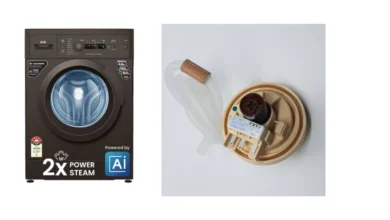

A crucial aspect of understanding precise load measurement in washing machines is exploring the various types of sensors employed in these appliances. Load cells, being a prevalent choice, come in different forms, each with its unique set of advantages and applications.

A. Load Cells

1. Strain Gauge Load Cells

Strain gauge load cells stand out as a popular choice due to their precision and reliability. These cells operate on the principle of electrical resistance variation in response to mechanical strain. As the load on the cell changes, the strain gauges deform, altering their resistance and producing an electrical signal proportional to the applied force.

2. Hydraulic Load Cells

While less common in washing machines due to their bulkiness, hydraulic load cells deserve mention. These cells utilize changes in hydraulic pressure to measure load. The force applied to the load cell causes a change in hydraulic pressure, and this change is then converted into an electrical signal.

B. Force Transducers

Force transducers, akin to load cells, convert applied force into an electrical signal. They exhibit versatility and find applications in various industries, including washing machines. These transducers often utilize piezoelectric or capacitive elements to detect force changes.

How Load Cells Work in Washing Machines

Understanding the intricate workings of load cells in washing machines is essential to appreciate their role in optimizing the washing process. This section will provide a detailed walkthrough of the installation, measurement process, and calibration of load cells.

A. Installation and Placement

Load cells are strategically placed within the washing machine structure, typically near the drum. This placement ensures direct exposure to the load, allowing for accurate measurements. The engineering precision in the placement of these sensors contributes significantly to their efficacy in capturing real-time load data.

B. Measurement Process

- Load Application: As users load clothes into the washing machine, the load cells sense the applied force, initiating the measurement process.

- Strain Detection: In the case of strain gauge load cells, the mechanical strain from the load causes deformation in the attached strain gauges. This deformation alters the electrical resistance in the gauges.

- Signal Conversion: The change in electrical resistance is then converted into an electrical signal. This signal is proportional to the force or weight applied to the load cell.

- Data Processing: The washing machine’s control system processes this signal, obtaining real-time information about the load size. This data is crucial for making informed decisions regarding water usage, spin speed, and detergent dispensing.

C. Calibration and Accuracy

Calibration is a critical aspect of ensuring the accuracy of load cell measurements. Manufacturers calibrate load cells during the production process, and some washing machines may offer user-initiated calibration routines to account for any changes in the load cell’s performance over time. This calibration process is essential to maintain precision throughout the appliance’s lifecycle.

Benefits of Precision Load Measurement in Washing Machines

The integration of precision sensors, particularly load cells, brings forth a myriad of benefits that contribute to the overall efficiency and sustainability of washing machines. This section will delve into these advantages in detail, emphasizing how precise load measurement optimizes resource usage and enhances cleaning performance.

A. Resource Optimization

- Water Usage: Accurate load measurements enable washing machines to dispense an optimal amount of water based on the load size. This not only conserves water but also reduces energy consumption associated with heating excess water.

- Detergent Efficiency: Precise load data allows the washing machine to adjust detergent quantities accordingly. Over time, this leads to significant savings in detergent usage, contributing to cost-effectiveness and environmental sustainability.

B. Improved Cleaning Performance

- Customized Washing Programs: Armed with precise load information, modern washing machines can tailor washing programs to different load sizes. This customization ensures thorough cleaning while avoiding unnecessary wear on clothes.

- Reduced Wear and Tear: By avoiding overloading, washing machines equipped with load cells minimize wear and tear on internal components. This prolongs the appliance’s lifespan and reduces maintenance requirements.

Energy Efficiency

- Optimized Spin Cycles: Load cells assist in determining the ideal spin speed based on the load weight. This optimization not only enhances cleaning efficiency but also contributes to energy savings during the spin cycle.

- Smart Power Management: Washing machines with load sensors can implement smart power management strategies, adjusting energy usage based on the load requirements at different stages of the washing process. This adaptability enhances overall energy efficiency, aligning with the growing focus on sustainable appliance design.

Challenges and Considerations

While precision sensors offer numerous advantages, there are considerations and challenges associated with their integration into washing machines. This section will delve into these aspects, providing a comprehensive understanding of the potential hurdles and solutions.

A. Cost Implications

The inclusion of advanced sensors, especially high-quality load cells, can contribute to the overall cost of the washing machine. Manufacturers often face the challenge of balancing affordability with the integration of cutting-edge technologies. However, it is essential to recognize that the long-term benefits, such as reduced resource consumption and enhanced appliance longevity, often outweigh the initial cost considerations.

B. Maintenance and Durability

Load cells are intricate components that may require periodic maintenance to ensure optimal performance. Additionally, factors such as vibrations and mechanical shocks during operation can impact their longevity. Manufacturers address these challenges through robust designs and materials, but regular user maintenance may still be necessary. Educating users on proper care and maintenance practices becomes crucial in maximizing the lifespan of appliances equipped with precision sensors.

Future Trends in Load Measurement Technology for Washing Machines

As technology continues to advance, the landscape of load measurement in washing machines is likely to undergo further transformations. This section will explore emerging trends and potential developments that could shape the future of load measurement technology in washing machines.

A. Integration with IoT

The Internet of Things (IoT) is making its presence felt in the realm of household appliances, and washing machines are no exception. Future iterations of washing machines may seamlessly integrate with IoT platforms, allowing users to monitor and control the appliance remotely. This connectivity opens up new possibilities for data analysis and machine learning algorithms to enhance the efficiency of washing processes.

1. Remote Monitoring and Control

Users may have the ability to check the status of their laundry remotely, receive notifications when cycles are complete, and even initiate or customize washing programs through dedicated mobile applications. This integration not only adds convenience to users’ lives but also contributes to a more intelligent and adaptive appliance ecosystem.

2. Data Analytics for Optimization

The data generated by load cells and other sensors can be harnessed for advanced analytics. Machine learning algorithms could analyze usage patterns, providing insights into optimal washing conditions for different fabrics and load sizes. This data-driven approach would further refine washing algorithms, leading to improved efficiency and performance.

B. Enhanced Sensor Fusion

As technology progresses, manufacturers might explore enhanced sensor fusion by combining load cells with other sensing technologies. This holistic approach could offer a more comprehensive understanding of the laundry composition and the washing environment.

1. Moisture Detection Sensors

Integration with moisture detection sensors could enable washing machines to adapt cycles based on the wetness of the clothes. This feature would not only contribute to better cleaning performance but also reduce unnecessary drying time, saving energy.

2. Optical Sensors for Fabric Recognition

Optical sensors capable of recognizing fabric types could enhance customization by adjusting washing parameters based on the specific requirements of different materials. This level of precision ensures that delicate fabrics receive gentler treatment, while more robust fabrics undergo a more rigorous cleaning process.

Conclusion

In conclusion, the integration of precision sensors, particularly load cells, has revolutionized the efficiency and sustainability of washing machines. These sensors provide accurate load measurements, enabling customized washing programs, resource optimization, and improved cleaning performance. While challenges exist, ongoing advancements in technology and a growing emphasis on smart home solutions point towards a promising future for load measurement in washing machines.

The historical journey from manual washing methods to the sophisticated washing machines of today reflects society’s continuous quest for convenience and efficiency. Precision sensors represent a pivotal chapter in this evolution, contributing not only to the ease of laundry but also aligning with contemporary priorities such as environmental sustainability and energy efficiency.

As consumers increasingly demand appliances that balance performance with responsible resource usage, manufacturers are likely to invest further in refining and innovating load measurement technologies. The integration of IoT and enhanced sensor fusion opens up exciting possibilities for the future, where washing machines may become even more intelligent, adaptable, and user-friendly.

In the coming years, we can anticipate a paradigm shift in the way we approach laundry, with washing machines evolving into smart, data-driven devices that cater to individual preferences and contribute to a more sustainable lifestyle. As technology continues to shape the future of household appliances, the role of precise load measurement in washing machines will undoubtedly remain at the forefront of innovation, ensuring that the chore of laundry becomes not just a task but a seamlessly integrated and efficient part of our daily lives.